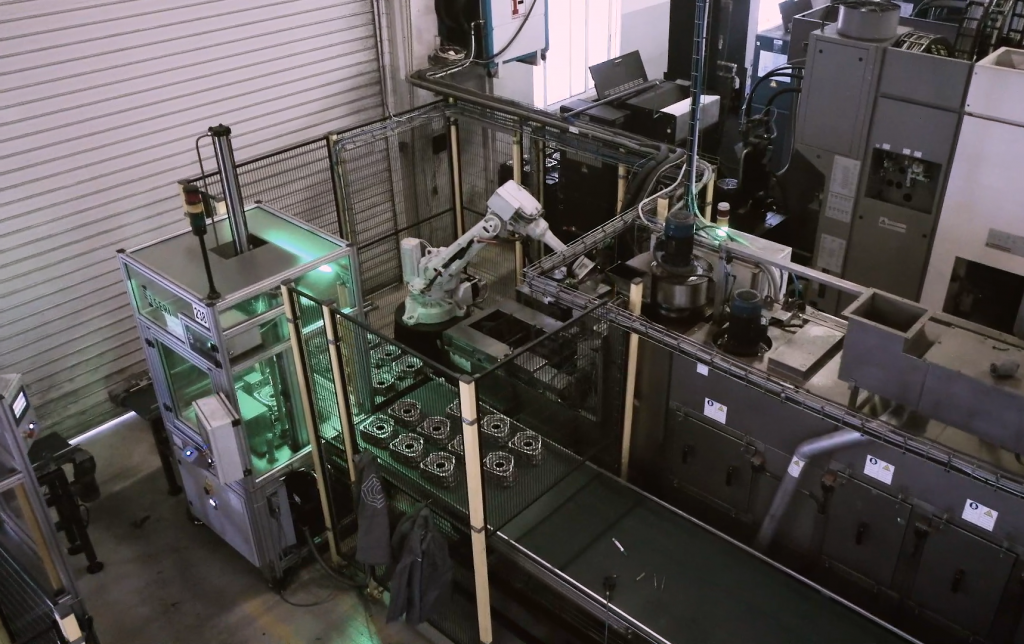

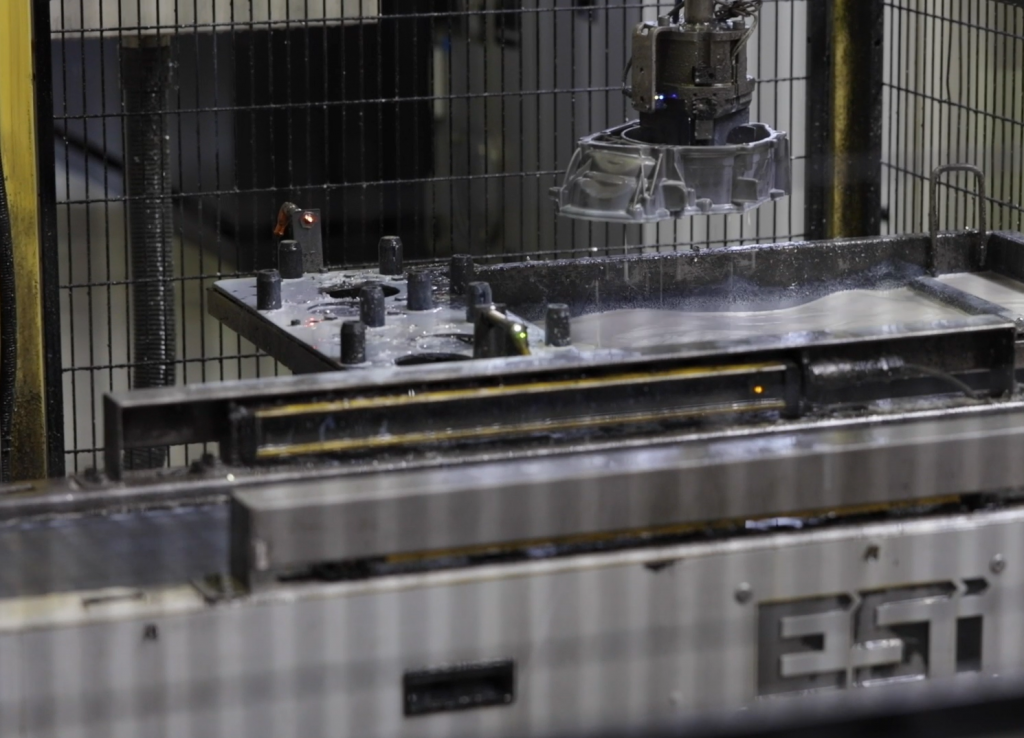

ESI was challenged by a company in the automotive sector to develop an industrial automation solution for the mass production of aluminum parts. In addition to the handling and feeding processes of the CNC machines, the washing and quality control processes (water tightness test/dimensional control) are also managed automatically.

In this industry, precision and accuracy are key elements since components are being produced for the automotive sector. Thus, the management and movement of parts with precision become crucial for the result and quality of the final product.

Industrial automation and the consequent optimization of production processes that result in increased productivity, cost reduction, and value creation were the focus and objectives of this project. Curious to know how this industrial solution developed by ESI works? Just keep reading!

Line Operation

First, the pieces are placed by an operator on the tray feeders, which are double, which means one of them is inside the cell feeding the robot, while the other is outside the cell being fed by the operator. It is supplied in two rows with ten pieces each and it peels off as soon as the tray inside is empty of any pieces. Giving access to the first two cells, the robots feed the CNC-Heller MC12 OP05/OP10 equipment and extract the parts after the machining operation to the next conveyor.

Lately, the parts are placed by the robot on the special conveyor with “nests”, where, further on, the parts are manipulated by the third robotic cell. They are then placed in the washing equipment. Once the parts are washed, they are extracted by the fourth robot and sent for drying and leak testing for quality control.

Finally, after the leak test for quality control, the parts are taken to two conveyors: depending on the result, the parts are either transported by the robot to the parts conveyor OK, in case they pass the leak test or are forwarded to the NOK output conveyor, in case they fail.

See the full video:

SEE ALSO: ESI Robotics Case Study - Fully Automatic End of Production Line